History

History

History

Traditional craftmanship & state of the art technology

Founded by expert diamond setter Giovanni Daems in 2003, DAEMS GIOVANNI began as a workshop creating unique, handmade pieces for global jewellery brands. Today, we have developed into a renowned centre of excellence with a global reputation for exceptional quality and innovative production in the jewellery, watch and luxury industry.

Our unique, custom-designed automated technology includes a patented, 100% accurate stone-setting application, a unique fully automated polishing process and the world’s first automated quality control system for polished precious metal surfaces.

This industry-leading innovation enables DAEMS GIOVANNI to carry out all production in Europe, delivering superior finished jewellery at highly competitive prices.

By continually investing in the development of new technologies and manufacturing processes, we also act as a strategic R&D partner for leading luxury watch and jewellery brands.

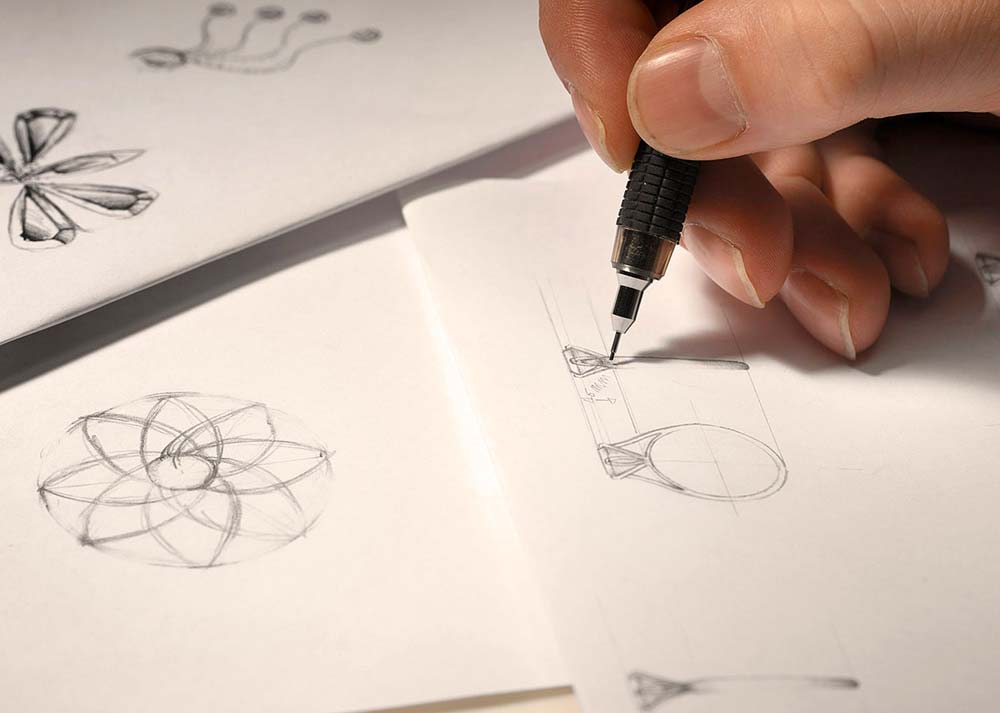

We combine patented innovation with the rare skills of traditional high class jewellery-making. Our master craftsmen are among the few able to create the most breathtaking one-off pieces, while also overseeing the automated production process. After all, the capability of our machinery depends on the expertise of man.

Unrivalled technology. Exquisite craftsmanship. Superior quality. And competitive costs. DAEMS GIOVANNI offers an utterly unique blend of tradition and technology.

Traditional craftmanship & state of the art technology

Founded by expert diamond setter Giovanni Daems in 2003, DAEMS GIOVANNI began as a workshop creating unique, handmade pieces for global jewellery brands. Today, we have developed into a renowned centre of excellence with a global reputation for exceptional quality and innovative production in the jewellery, watch and luxury industry.

Our unique, custom-designed automated technology includes a patented, 100% accurate stone-setting application, a unique fully automated polishing process and the world’s first automated quality control system for polished precious metal surfaces.

This industry-leading innovation enables DAEMS GIOVANNI to carry out all production in Europe, delivering superior finished jewellery at highly competitive prices.

By continually investing in the development of new technologies and manufacturing processes, we also act as a strategic R&D partner for leading luxury watch and jewellery brands.

We combine patented innovation with the rare skills of traditional high class jewellery-making. Our master craftsmen are among the few able to create the most breathtaking one-off pieces, while also overseeing the automated production process. After all, the capability of our machinery depends on the expertise of man.

Unrivalled technology. Exquisite craftsmanship. Superior quality. And competitive costs. DAEMS GIOVANNI offers an utterly unique blend of tradition and technology.

Achievements throughout the years

Giovanni Daems, descended from a family of diamond craftsmen, is recognised as a leading diamond setter.

DAEMS GIOVANNI is established in Kessel, 25km from Antwerp and for a century the global hub of diamond manufacturing.

DAEMS GIOVANNI pioneers the world’s first automated diamond setting machine, perfectly imitating the manual skill of an expert setter while improving accuracy and consistency. Development of computer aided diamond setting software (CADS)

DAEMS GIOVANNI develops a new kind of fully automated polishing robot delivering unprecedented accuracy.

DAEMS GIOVANNI opens a dedicated on-site R&D centre to support innovation and advise partners.

DAEMS GIOVANNI launches an integrated, automated quality control system for polished surfaces.

DAEMS GIOVANNI develops the patented ema clasp, a superior earring mechanism application delivering outstanding security and endurance, a substantial improvement on the classic spring-loaded earring back.

Production capacity expansion with new investment partner. Installation of additional five axis CNC milling machines and ultra-high precision Swiss lathes for the fabrication of extremely tight tolerance components for the watch and jewelry industry

Our Expertise

Learn how we excel in traditional jewellery-making

Our Technology

View our custom-designed robotic production

Your benefits

Discover the 7 key benefits of becoming our partner